Hollow Rotary Platform Servo Reducer Vertical Rotary Table

Overview Our Advantages Hollow rotary platform servo reducer vertical rotary table The rotary platform reducer uses para

Send your inquiryDESCRIPTION

OverviewBasic Info.

| Model NO. | RPA085-15 |

| Processing Trade | Processing with Material Supplied |

| Certification | ISO9001: 2000 |

| Customized | Customized |

| Specification | RPA85-L1 |

| Trademark | PLANETX |

| Origin | China |

| HS Code | 8483409090 |

Product Description

Our AdvantagesHollow rotary platform servo reducer vertical rotary table

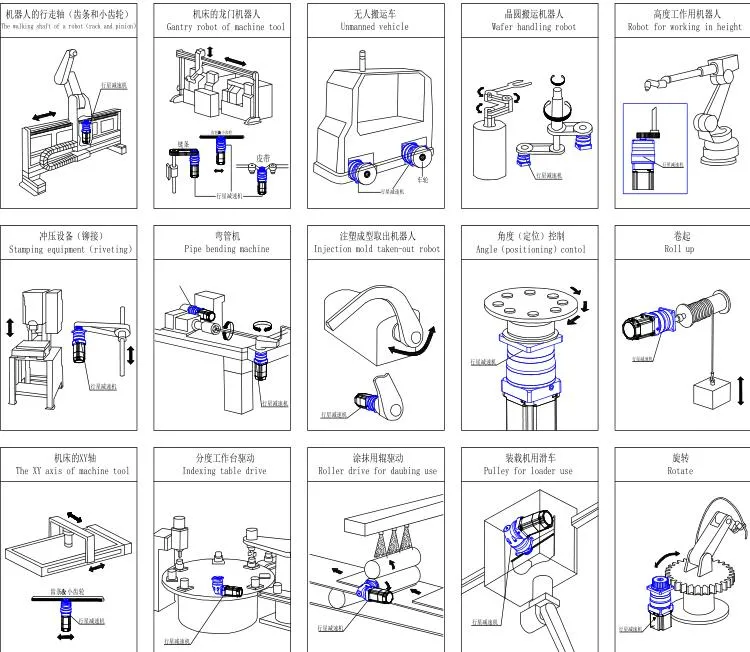

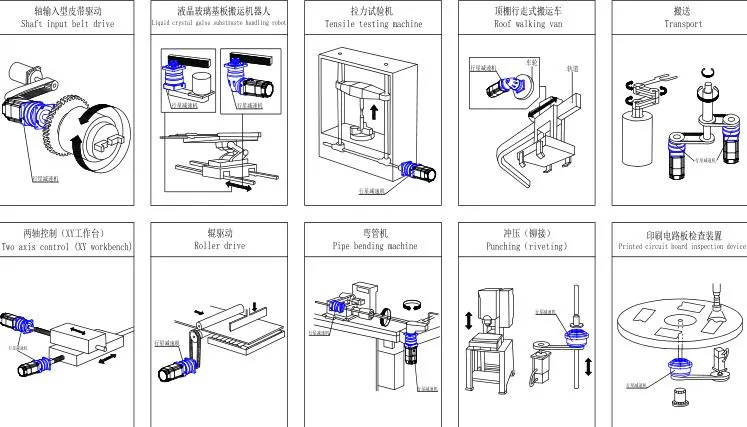

The rotary platform reducer uses parallel axis helical teeth and cross roller bearings to achieve hollow threading, deceleration, and increase rotational inertia. This type of reducer can be directly used as a slewing support, with a slewing accuracy of less than 20 arcseconds, and is widely used in the 3C electronics industry and precision machine tools. The speed ratios of the rotary platform reducer are 5, 10, 15, and 18, and other ratios need to be further developed. Used in conjunction with motors ranging from 50 watts to 750 watts. Box numbers are classified into four categories: 60, 85, 130, and 200.

The application scope of rotating platforms: Rotating platforms are characterized by ultra-heavy load, high rotation accuracy, and low clearance. Their product categories include shaft type, side shaft type, There are three types of right angle structures, mainly suitable for robotic arms, CNC turntables, alignment mechanisms, military radars, automation, measurement, and experimental fields that require high accuracy. Steps for selecting a rotating platform:

1. Select the size of the turntable based on the size of the workpiece; 2. Determine the model based on the size of the turntable; 3. Select the reduction ratio based on the rotational speed and transmitted torque; 4. Select the positioning method based on the installation method; 5. Select the accuracy according to the working conditions.

Hollow rotating platforms can be used for:

1. Rotating workbench in production line automation transformation;

2. Rotating chucks in laser marking or engraving machines;

3. Rotating axis in precision alignment mechanism;

4. Light load robotic arm joint;

5. High precision gear direct drive;

6. High precision, high torque, high rigidity, easy to use, combined with high-performance closed-loop stepper motors;

The hollow rotating platform is currently a blank in the market, directly replacing cam splitters and DD motors. The hollow rotating platform is a high-precision digital rotating platform with the advantage of low cost and high accuracy, occupying a strong market in the rotating platform category.

| Model | Unit | RPA060 | RPA085 | RPA130 | RPA200 | RPA280 | RPA450 | Ratios |

| Rated output torque | Nm | 6.0 | 35.0 | - | - | - | - | 5 |

| 3.5 | 18.0 | 50.0 | 90.0 | 150.0 | 450.0 | 10 | ||

| - | 7.5 | - | - | - | - | 15 | ||

| - | - | 25.0 | 50.0 | - | - | 18 | ||

| Stop fault torque | Nm | 3 *Nominal torqute | ||||||

| No load torque | 0.1 | 0.18 | 0.6 | 1.2 | 1.8 | 2.6 | ||

| Load bearing type | Cross roller bearing RPA6028 | Cross roller bearing RPA8533 | Cross roller bearing RPA13062 | Cross roller bearing RPA200100 | Cross roller bearing RPA280150 | Cross roller bearing RPA450150 | ||

| Maximum permissible radial force | N | 1800 | 4500 | 8000 | 12000 | 12500 | 18500 | |

| Maximum allowable axial force | N | 1800 | 4500 | 8000 | 12000 | 12500 | 18500 | |

| Nm/arcmin | Nm | 120 | 340 | 1000 | 2200 | 3000 | 4000 | |

| Torsional rigidity | Nm/arcmin | 2.4 | 5.8 | 16.0 | 28.5 | 40.0 | 55.0 | |

| Platform end face runout | mm | ≤0.01 | ≤0.01 | ≤0.01 | ≤0.01 | ≤0.02 | ≤0.02 | |

| Platform radial runout | mm | ≤0.01 | ≤0.01 | ≤0.01 | ≤0.01 | ≤0.02 | ≤0.02 | |

| Rotary accuracy | acrmin | ≤1(±0.5) | ≤1(±0.5) | ≤1(±0.5) | ≤1(±0.5) | ≤1(±0.5) | ≤1(±0.5) | |

| Rated output speed | rpm | 200 | 200 | 200 | 150 | 100 | 100 | |

| Maximum output speed | rpm | 500 | 450 | 350 | 300 | 200 | 200 | |

| Body weight | Kg | 0.55 | 1.4(1.1) | 2.5 | 8.8 | 25 | 40 | |

| Design bearing | Kg | 10 | 22 | 50 | 120 | 160 | 300 | |

| Noise | dB | ≤55 | ≤55 | ≤58 | ≤62 | ≤65 | ≤68 | |

| Lifetime | h | 20000 | ||||||

| Minimum operating temperature | ºC | +90 | ||||||

| Degree of protection | IP | IP65 | ||||||

| Lubrication method | Long term lubrication | |||||||

| Installation method | Any | |||||||

| Direction of rotation | Output, input reverse | |||||||

| Full load efficiency | % | 50% | ||||||

Reliable guarantee

https://cbc236daf94c567b.en.made-in-china.com/product-list-1.htmlWe strive to be meticulous in every process and perfect in every detail. Integrate the production management system, inspection and test system, quality control system, etc. into the production process of all products, widely use advanced technology, production and inspection equipment, and truly achieve high quality and high standard service for customers at home and abroad!

Q: How to get a quick quote

A: Please provide the following information when contacting us

- Motor brand

- Motor model

- Motor dimension drawing

- What is the gear ratio

A: We all install it now, but it takes 3-5 days if it is not non-standard. Non standard 10-15 days, depending on the specific situation

Q:Do you provide samples, free or extra

A: A: You can reserve one first, and purchase it on demand